KYB recommends that suspension specialist workshops should have

access to this range of professional tools, for safe and efficient

replacement of suspension components.

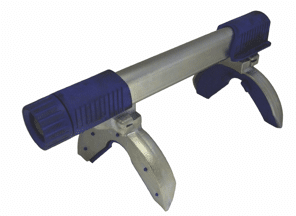

This equipment is for assembling and disassembling struts and coil springs in the safest way. Auto levelling upper arms simplify working on conical and misaligned springs and the brackets system has front and side spring clamps designed for fast changeover. The safety guard is important for operator safety and also allows the strut to be safely left in-situ.

Torque wrenches should be calibrated regularly, especially with high levels of usage. Vehicle specific torque settings can be found in our Suspension Solutions App.

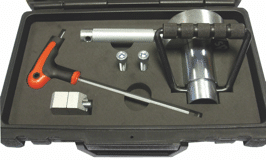

This is for shock absorbers fitted with internal rebound springs. The strut controller tool is able to extend the piston rod, allowing it to be accessed easily.

For more information about rebound springs, see our technical bulletin

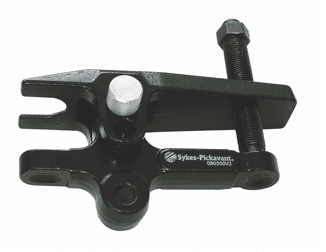

This is used regularly when changing most strut type front shock absorbers. Generally front struts slide into a split hub carrier which then needs to be tightened, clamping the shock absorber to the hub assembly. When replacing the suspension, this split hub need to be opened up to allow the removal of the old shock absorber.

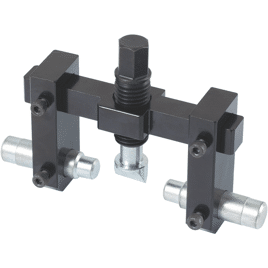

Universal set for the removal and installation of flanges and wheel bearings, without the need for removal of suspension struts or wheel hubs from the vehicle (where access permits). Remove and install wheel bearing without hub removal. This tool virtually eliminates damage to vehicle components and reduces the time taken to complete the overall job.

This is a universal system for the removal and installation of suspension bushes, bearings and seals. By selecting the appropriate diameter sleeves, the bush / bearing / seal is pressed or pulled by the action of turning the spindle nuts in opposing directions.